While you're not using your boat as much as in the height of the summer, winter is the perfect time to get to grips with regular maintenance – and it doesn't come more important than antifouling.

New Zealand boaties are understandably proud of our magnificent coastal sailing and inland waterways, but it’s important we all do our bit to make sure our playground doesn’t become infested with invasive marine pests. The key way to do this is if your boat spends any serious amount of time moored in the water, haul it out and give its' bottom a good clean and repaint with antifoul. You can find everything you need to carry out this vital work at Burnsco and if you want any more information about keeping your craft from becoming a biosecurity hazard, here’s a link to the Government’s comprehensive list to identifying marine pests and step-by-step guide to bio-friendly boating.

So to get the ball rolling, here’s our complete guide to antifouling and why it’s not only important for your own craft but the enjoyment of all New Zealand’s boaties.

1. Why do you need antifouling?

Antifouling, as its name suggests, prevents fouling of the boat – that is, all those hitchhiking pests such as barnacles, slime and weed which attach to the bottom of the boat. As well as helping to keep these pests out of the foodchain, antifouling also prevents them from causing damage to the hull, reducing its speed through the water, and affecting fuel economy. Antifouling does this by slowly releasing biocides which hinder the growth or repel underwater life. Most antifouling contains copper compounds.

2. Types of antifouling

The antifouling paint should be suitable not just for the type of hull you have but also for the way in which you use the boat. Never use copper based antifouling on an aluminium boat or an aluminium drive unit (eg sail drive or stern leg) because it will corrode the aluminium through electrolysis.

Antifouling paints can be classified as either:

Soft (“eroding” or “ablative” type) – partially water-soluble so as the water passes across the hull its action reduces the thickness of the antifouling and wears away, much like a bar of soap.

Hard (“contact leaching” type) – paint dries to a hard, burnishable surface that is porous and packed with biocides. During the season, the biocides leach out on contact with water in a controlled manner, until finally exhausted and only a hard film remains.

From softest to hardest, Burnsco’s stock of antifouling is Micron Extra, Altex No.5/Micron66, Altex No.10, Awlcraft, Ultra and Trilux.

Soft antifouling splits into two types:

Ablative (eg No. 5, Awlcraft) – erodes unevenly, wears off faster where water flow past surface is greater, so not always suitable for high speed craft which are used frequently as the thickness of the film may be reduced too quickly; can be left out of the water for long periods.

Self-polishing (eg Micron Extra, Micron 66) – erodes evenly with no highs and lows giving a smooth surface, reducing drag and improving fuel economy.

3. Know your regulations

Over the past few years, the Government’s Environmental Protection Agency has been introducing new rules about how antifouling paints are produced, used and applied.

The most important changes are that importers and manufacturers must provide more safety info on the cans and, from July 1, 2015, anywhere antifouling is being sanded, scrubbed down or painted must be clearly designated as a Controlled Work Area.

Effectively this means having to wear proper protective equipment, display signage that the work is being carried out, and collect and dispose of all waste in accordance with strict regulations. If you’re getting the work done by a pro then they’ll have this all under control, but you won’t be able to dry-sand existing antifouling and if you’re using a spray application then you’ll need proper respiratory gear. Brushes and rollers are still fine.

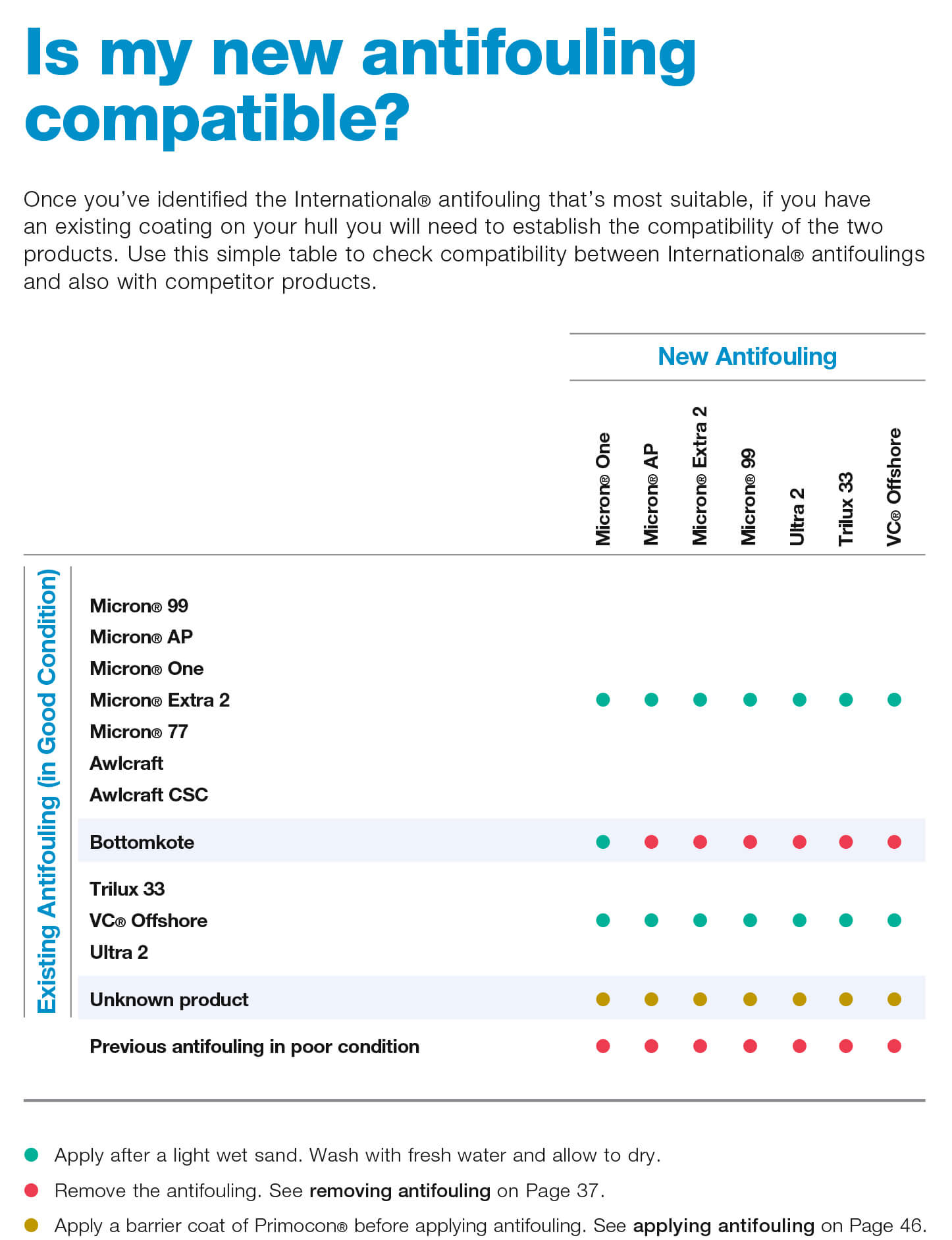

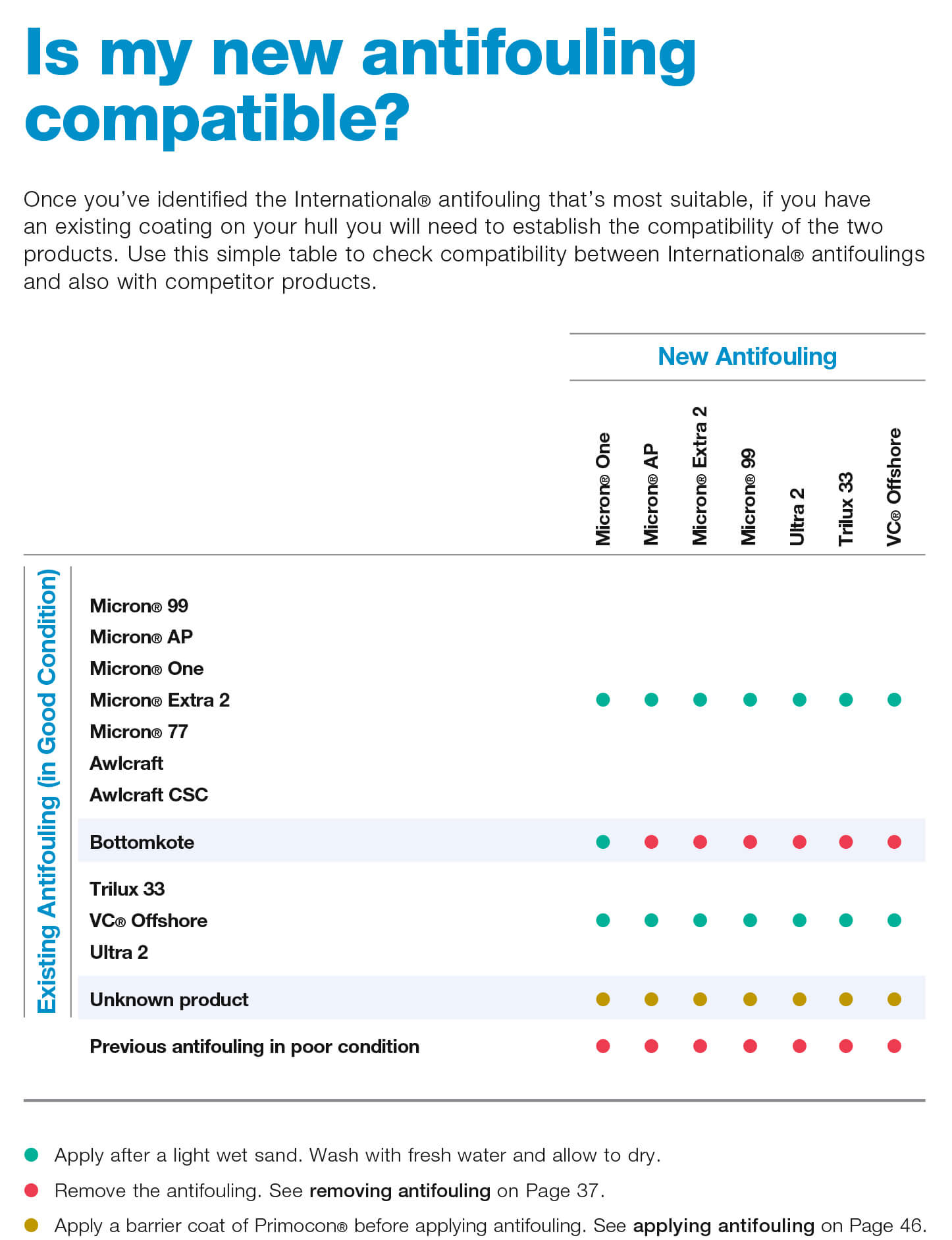

4. Compatibility

If you’re redoing your antifoul for the umpteenth time then you’ll know what type you have used in the past. But if you’re applying a first coat to a “new” second-hand boat or for the first time then it’s vital to make sure you’re using something which is compatible with what was on the hull before.

The first step is to try and establish what the old antifouling is. Do you have the old paint tin lying about? If you are a new owner, can you ask the previous owner what they used for antifouling. If you’re still unsure, wet the boat and rub the hull with your hand to find out whether it’s hard or soft. The old rule of thumb is that you can put soft on hard but not hard on soft. However, the products have now changed and in the International range you can put hard on soft.

Generally you have three options

Known antifouling: Check for compatibility – see our chart in this article

Unknown antifouling and in good shape: Sand back where necessary and apply a tie coat of Primocon

Unknown antifouling and in bad shape: Remove old coats of antifouling, prime and then antifoul.

And remember when you’re applying antifouling this time, keep a tin handy so you know what type you used the next time you’re visiting us to buy more.

5. What else will you need?

Primers: If you’re dealing with a previously unpainted surface, the type of primer you need depends on what the hull is made from with clear differences between wooden craft, aluminium, and boats made from glass reinforced plastic, steel, iron or lead. Contact us to make sure you get the right info.

As an alternative to a paint system, use a waterproof coating such as Lanocote (aerosol or tub), Soft Seal or Heavy Duty Corrosion Inhibitor on shafts, rudders, keels and props.

Protective gear: Dust masks and overalls are important to stop any unwanted inhilation of dust and to keep regular clothing clean.

Cleaning and application gear: Masking tape, wet and dry sand paper, paint brushes, roller and trays, tack cloths, turps and thinners are all needed to complete the job properly, efficiently and to a high standard.

Do you have any questions?

Please, contact our friendly team on 0800 102041 or email: website@burnsco.co.nz

We provide general information on products, not personal advice. Always seek the help of a relevant tradesperson if you have a technical query.